SERVICES

We provide consistent services (Consistent production process), undertake from your design ideas, discuss the process, sample confirmed and packages to the mass production, it will save your time. We can control all the quality and accuracy of our products at every stage. We have a strong team of masters, also cultivate a more excellent technical team and gradually update the machine equipment. We also have large CNC machine to fully meet the customer's customized needs, from manufacturing process, samples to mass production. The whole process is checked to ensure the highest quality.

Made In Taiwan

Attentive

Specialty

service

Manual and machine process

The warmth of wood products is from the temperature of each hand in each process.

The manufacturing process is complicated and there are many machines. We will introduce several ways to let you know more.

Wood material

From purchase wood material, ready for follow-up.

Measure size

We convert all customized products into CAD files of product drawings, so that the size of each batch production is based on the drawing size as a standard basis, ensuring that the size of each batch is within the normal tolerance range.

Tool Machine - Sawing Machine

There are all kinds of machine tools at the factory, whether it is a saw table, planer... etc., they are mostly used to prepare and cut all kinds of wood.

Glued wood frame

Each wooden box starts with material preparation and goes through dozens of processes, and each process is confirmed by the factory supervisor.

Sanding stage

This is one of the sanding machines. Each product and each process has its own sanding method to meet our needs.

Wooden box cut cover

Our wooden box production will basically be one-to-one production to make sure the matching of the wooden box and the consistency of the matching wood grain between the cover and body until the final quality inspection and packing.

Drilling machine

Drill holes according to the hole position required by each product.

Coating process

Each painting process will use different painting methods according to the product.

Sanding again after coating

Spray paint is not only spray paint, it needs to be processed according to the difference of each product, sanded after painting and painting again, which is why we need to have our own spray paint production line to ensure quality.

Coating finished

The manufacturing process of each product is really complicated, but the quality of the finished product is also obvious.

Tool wall

We have a variety of tools for various designs.

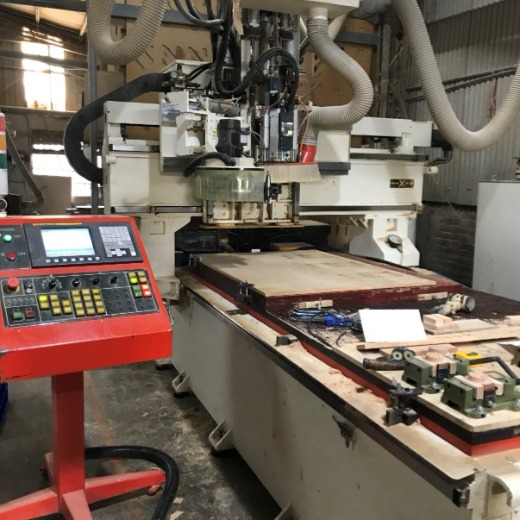

CNC machine

In order to increase the accuracy of the product and the feasibility of the design, the CNC machine is an indispensable partner. At the same time, we also have professional engineers to set up to ensure the accuracy of execution.

Double-ended cutting tool